Direct Mail Adhesives

APPLIED Adhesives can be your single direct mail adhesives source for the following pressroom needs:

- Water-based and hot melt adhesives for remoistenable (convection air and IR dryable), lamination, pocket-/closed-end mailer, and spine applications.

- Water-based repositionable, microsphere adhesives (Post-It adhesives)

- EVA-based and pressure-sensitive hot melt adhesives for spine gluing applications.

- Full range of low-stain fugitive hot melts based on specific release needs.

- Cold-seal adhesives for lamination and pocket-/closed-end mailers.

- UV scratch-off (gold and silver coatings) with custom, compatible release coatings.

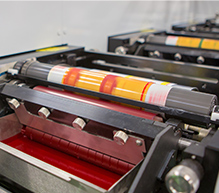

- Full range of aesthetic and functional water-based and UV coatings covering the full scope of wide web heat set, narrow web flexo, sheet fed, and digital press applications.

- Our GATF award-winning integrated label technology for producing in-line finished pressure sensitive adhesive labels, stickers, and fully in-line finished security envelopes utilizing pressure sensitive water-based or hot melt adhesives (both general purpose permanent, laser grade, freezer grade, and repositionable adhesives) and compatible UV or heat-set silicone coatings.