Are you using the most effective and efficient adhesive and dispensing equipment for your needs?

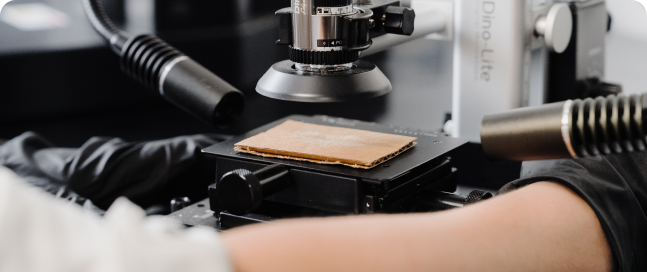

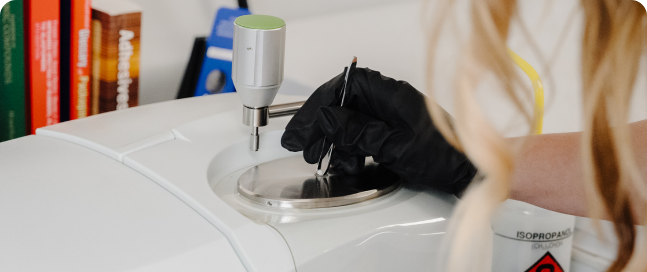

Using advanced industrial adhesive and dispensing equipment boosts efficiency and also improves overall production quality. At APPLIED Adhesives, our expert technical service team is dedicated to maximizing your production line efficiency and perfecting your adhesive selection and application processes.

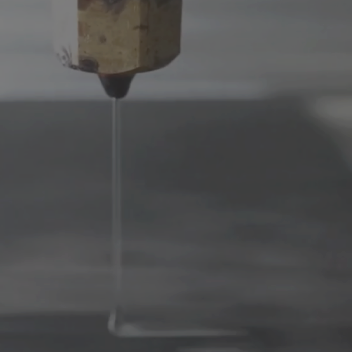

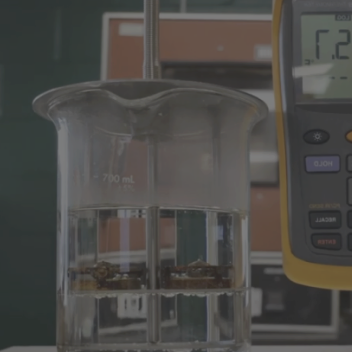

Our comprehensive adhesive and equipment evaluation service identifies and rectifies adhesive over- and underuse, providing tailored recommendations based on your needs. By leveraging the industry’s most innovative technology, we help you avoid bottlenecks and inefficiencies, ensuring smooth and optimized operations.

Supporting more than 60 industries across North America, our application experts provide solutions designed for your Advanced Fluid Dispensing, Automotive, End-of-Line Packaging, Paper Converting, Graphic Arts, and Product Assembly applications.