The importance of maintaining clean machinery and equipment is something nearly all industries have in common. However, keeping your machinery clean and free of grease, grime, and adhesive build-up is an especially critical part of the maintenance routine in the packaging industry, especially when it comes to hot-melt machinery parts.

Why Clean Your Machinery?

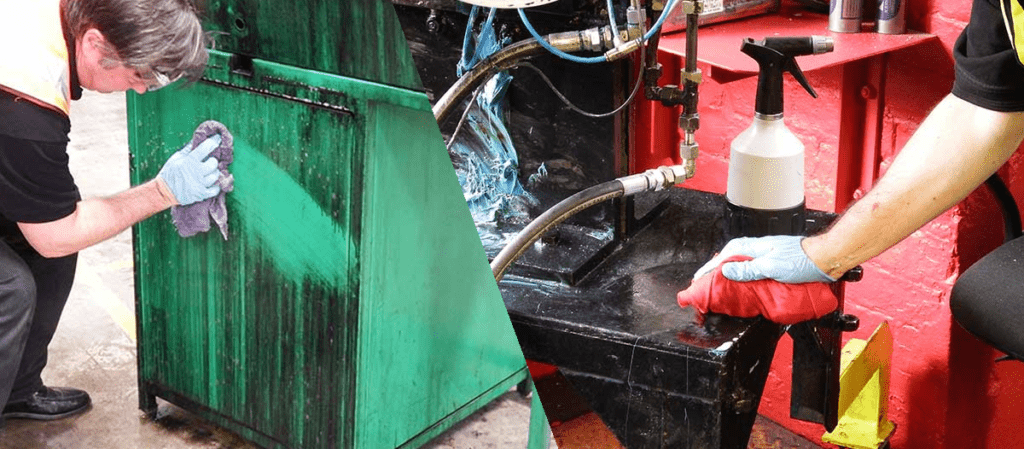

Having machinery cleaned and degreased regularly should be a part of your regular preventative maintenance program. Machinery that is regularly and thoroughly cleaned has a longer life span and can function more efficiently throughout its life. In addition, clean equipment presents fewer workplace hazards and provides a safer environment for workers. Finally, clean machinery allows you to get the most out of your hot melt and other adhesive products.

To function effectively, your machinery needs to be free of grime, char, and other harmful residues. Unfortunately, grease, grime, and adhesives can easily build up and prevent these dynamic machines from performing their tasks. Choosing an effective and safe cleaner to take care of your company’s machinery is crucial to the success of your team, and equipment. It’s important to consider the grime you’re cleaning as well as the products available so you can make an informed decision when choosing your industrial cleaner.

Types of Grime

There are three major types of grime that affect machinery in all industries:

- Organic grime refers to anything derived from living material. For example, hydrocarbons like lubrication grease, heavy oil, vegetable oil, petroleum products, and fuel are considered organic grime.

- Inorganic grime refers to dust, dirt, sand, clay, mineral buildup, rust, or scale.

- Perhaps the most common grime across all industries, mixed grime refers to a mixture of organic and inorganic compounds bound together.

Mixed grime occurs when organic grime binds with and traps inorganic grime like dirt, rust and adhesives. Most industrial cleaners have degreasing qualities because they must be able to lift greases, oils, and the inorganic grime they trap.

Types of Cleaning Agents and Degreasers

Depending on the type of machinery and surface material, as well as the nature of the grime and contaminants affecting it, there are a few different cleaning agents and degreasers you may choose from:

- Industrial solvents. Solvents are a compound that dissolves other compounds or materials placed within it. For example, nail polish remover, paint thinner, and trichloroethylene (TCE) can act as solvents. Organic solvents can effectively dissolve grease and other fat-based compounds.

- Detergents are water-based, non-flammable, and pose few threats to the workplace environment or to the health and safety of the workers. Many detergents are also biodegradable, making them easier to safely dispose of than industrial solvents. Detergents include compounds called surfactants, which act by reducing the surface tension of water, allowing it to clean machinery parts.

- Acid and alkali cleaners. Acid and alkali cleaners are chemical cleaning agents known for their aggressive removal of all types of grime from any surface. Acidic cleaners can remove substances like starches and carbonates, while alkali cleaners remove oils, greases, and organic residue.

- Citrus-based cleaners. Citrus-based cleaners are eco-friendly, safe, and non-toxic. Citrus-based cleaners are derived from orange and other citrus fruit peels and are effective in removing both organic, inorganic, and mixed compounds from all types of machinery and surfaces. Citrus cleaners are fortified with citrus-based cleaning compounds that can safely remove grease, rust, dirt, and grime from industrial machinery as effectively as other industrial cleaners.

Issues with Traditional Solvents and Cleaners

Unfortunately, not all the above listed products are ideal for the industry you’re in. Some potential issues include:

- Solvent issues. Despite their ability to clean up organic compounds, solvents are harmful to the environment and are difficult to dispose of safely. Solvents also give off toxic fumes, which are harmful to air quality and are highly flammable. As a result, solvents can pose many dangers to workers.

- Detergent issues. Despite the environmental advantages of using water-based detergents instead of solvents, detergents are not particularly effective at removing grime, rust, and scale from industrial machinery. Therefore, detergents are not the first choice for many packaging experts who need a cleaning solution capable of thoroughly removing mixed compounds from hot melt machinery.

- Acid and alkali cleaner issues. Due to their highly aggressive stripping nature, these cleaners may damage more sensitive surfaces during the cleaning process. Acid and alkali cleaners can even pose burn risks to workers, increasing the potential for workplace injuries.

Advantages of Organic, Citrus-Based Cleaners

Fortunately, citrus-based cleaners and degreasers address many of these issues. There are three main reasons why citrus-based cleaners like Melt-O-Clean are gaining popularity within the packaging industry as well as other industries:

- Safer for employees. Unlike some of the other industrial cleaning solutions on the market, citrus-based cleaners pose little to no threat to workers or the working environment. Citrus cleaners do not release toxic fumes, are not flammable and pose no risk of burn or other injuries. For this reason, no specialty equipment or protective gear needs to be worn when using this cleaner.

- Better for the environment. Other industrial cleaning agents release noxious fumes and toxins into the air, which have damaged the ozone layer and negatively impacted air quality. Furthermore, if these cleaners are not properly disposed of, they are liable to pollute groundwater, streams, and other water sources. Citrus-based cleaners are made with completely biodegradable, natural substances that do not negatively affect air or water quality during use or disposal.

- Multi-purpose and cost-efficient. Citrus-based cleaners have been proven to remove all forms of grime, including organic, inorganic, and mixed compounds. Citrus cleaners can remove tough grease and grime, rust, and scale from all manner of parts, metals, and materials without damage. As a result, one cleaner can often be used for many parts, reducing your maintenance budget.

Choosing the right cleaning solution for your machinery is key to maintaining a safe, clean, and efficient workplace. APPLIED Adhesives has been a reliable and trusted source for packaging industry adhesives, labels, and cleaners for over 25 years. We understand the need for a clean, efficient, and productive manufacturing and packing process and have worked hard to help you achieve the same for your business. Contact APPLIED Adhesives today to learn more about our citrus-based cleaning solutions or to discover how we can help you develop a tailored solution for your packaging needs.

Resources:

https://www.envirofluid.com/articles/industrial-degreasing-cleaning-how-industrial-degreasers-cleaners-work/

https://www.chemtronics.com/ultimate-guide-to-degreasers-precision-cleaners

https://www.omegasonics.com/knowledge-center/blog/solvents-vs-detergents-whats-the-difference/

https://www.envirotechint.com/vapor-degreasing-explained/

https://www2.illinois.gov/epa/topics/air-quality/fact-sheets/Pages/cold-cleaning.aspx

https://ecolink.com/info/making-industrial-cleaning-safer-with-citrus-degreasers/

https://www.premierpacks.com/catalog-confirmation/16-news/53-the-perfect-cleaner-and-degreaser