Construction and Industrial Applications

The Legacy of Adhesive Systems Technology (AST)

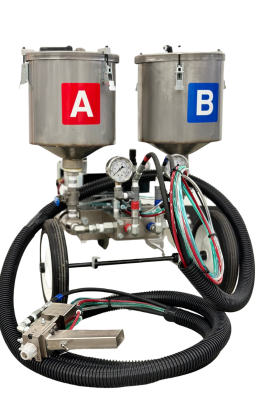

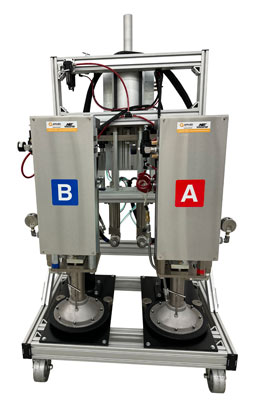

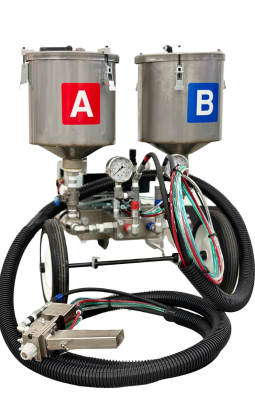

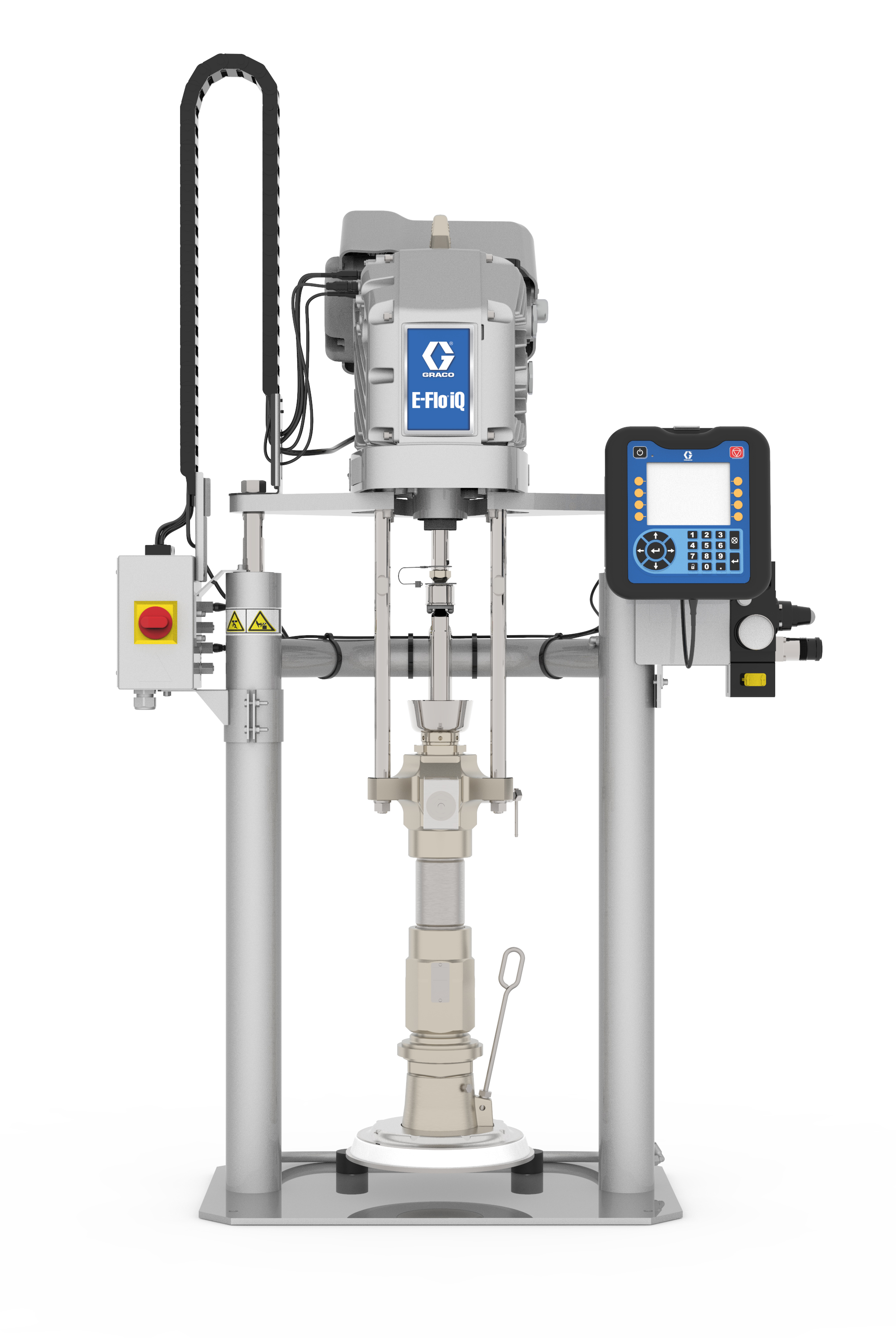

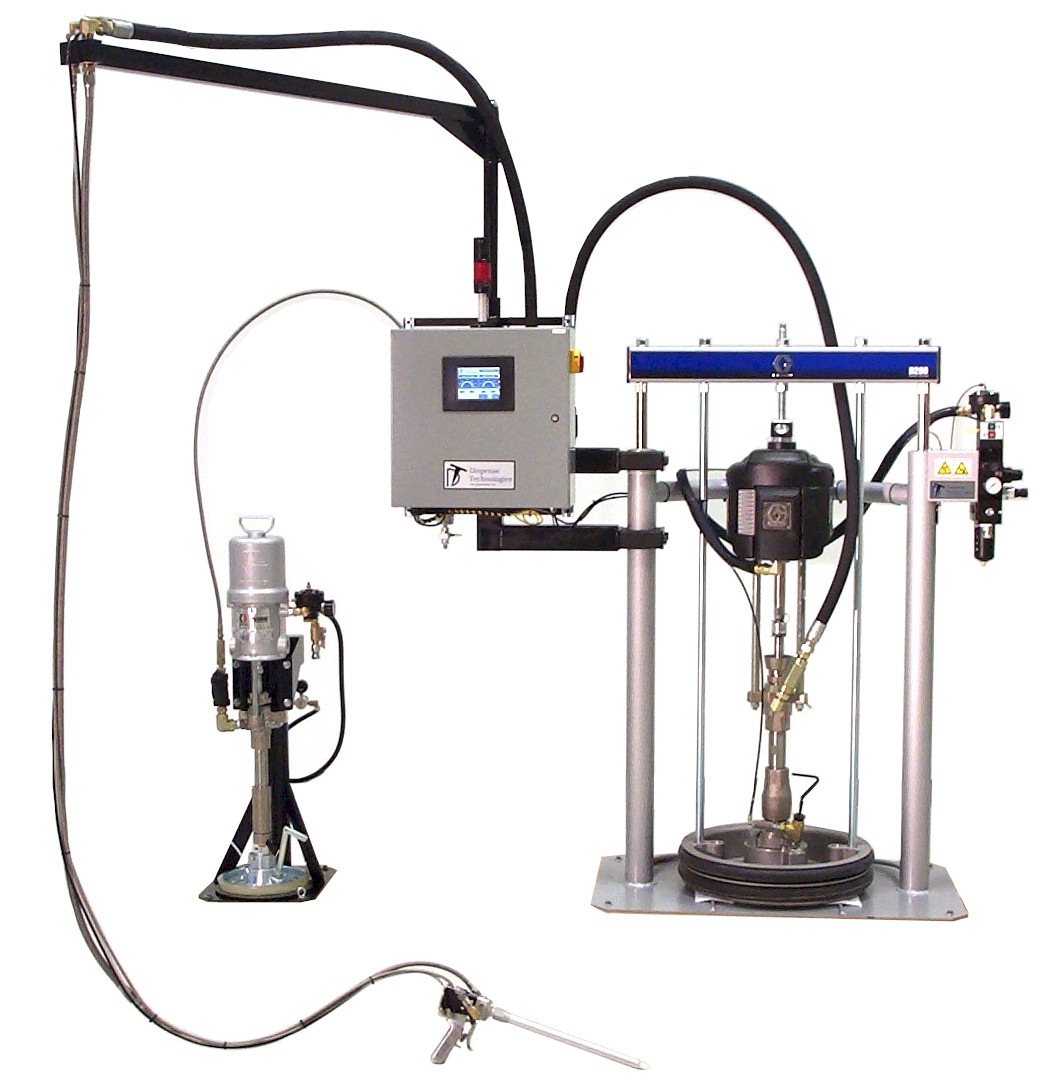

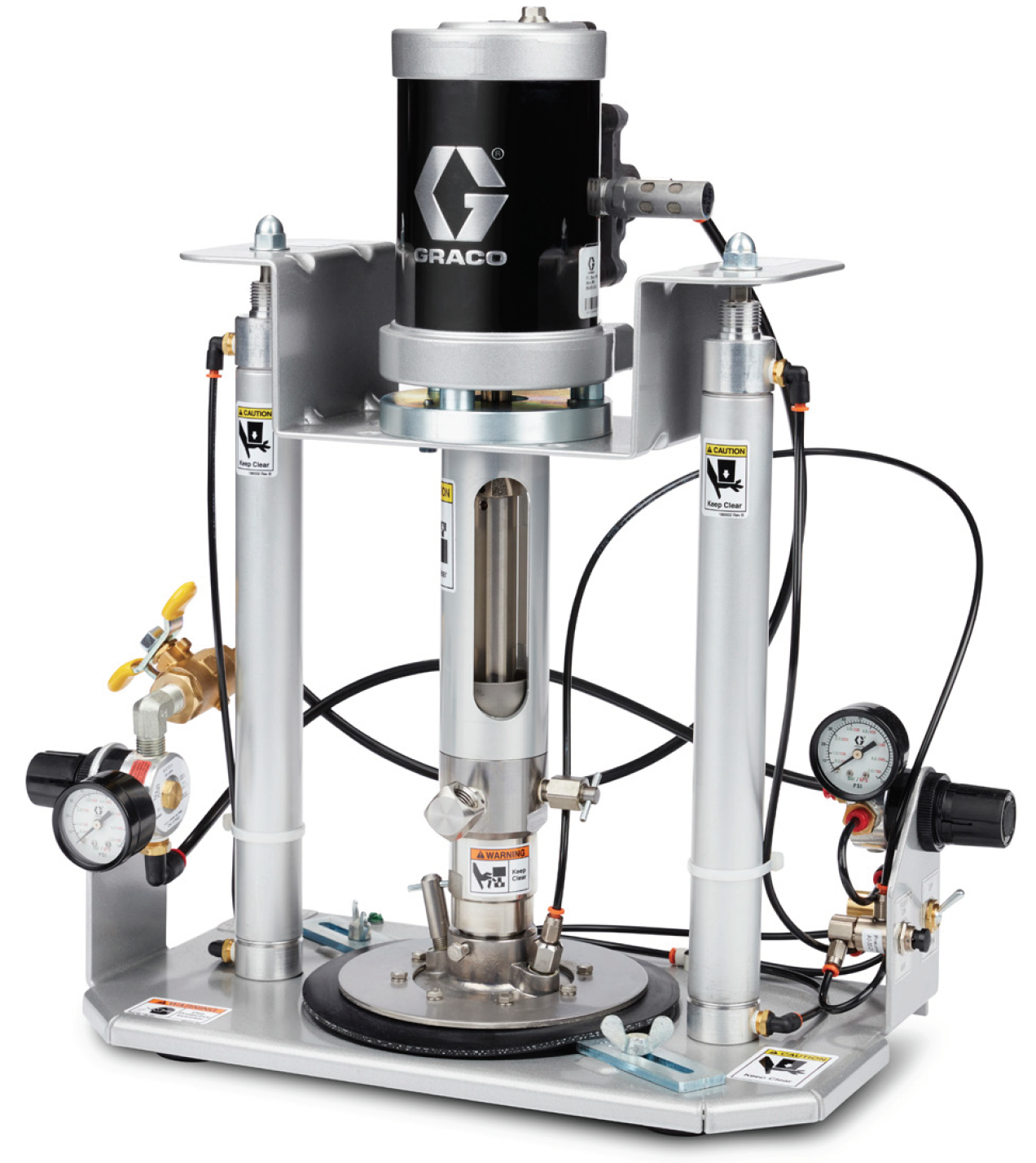

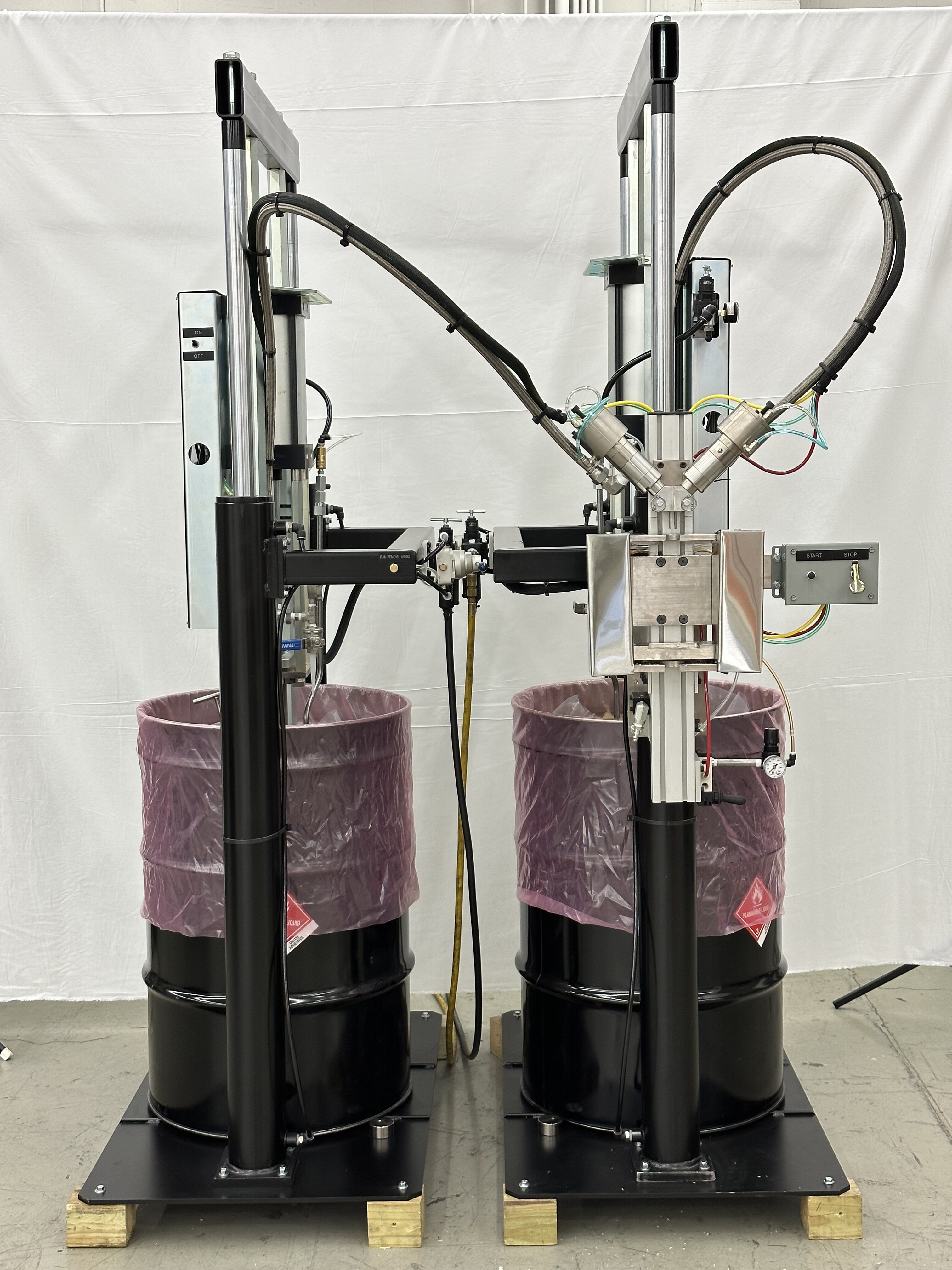

APPLIED Adhesives Equipment Solutions designs and manufactures meter, mix, and dispensing systems for adhesives and sealants. Engineered and developed for the industrial and construction markets, these equipment solutions are designed to fit the unique needs of our customers.

Quality and performance standards are at the heart of everything we do and develop, and we’re proud to manufacture reliable, cost-effective, highly efficient, mixing and adhesive dosing systems.

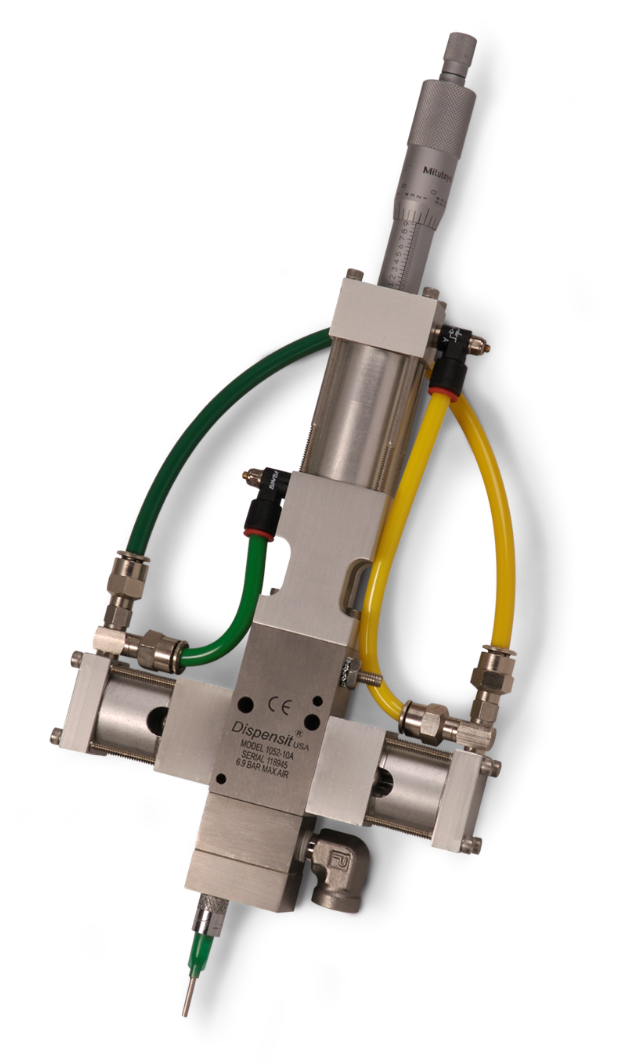

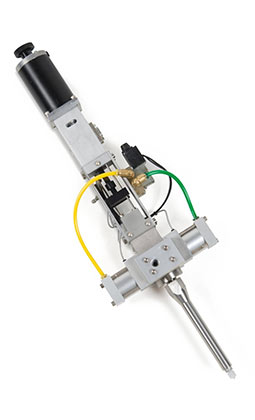

APPLIED Adhesives offers dispensing equipment for a variety of single and dual component materials. APPLIED Adhesives also provides cylinder, gear, and rod metering pumps that demonstrate our commitment to providing the highest quality solutions for all applications.

To learn more about AST equipment, please contact 763-592-2060.

To purchase AST parts, please click here to visit our e-commerce site.