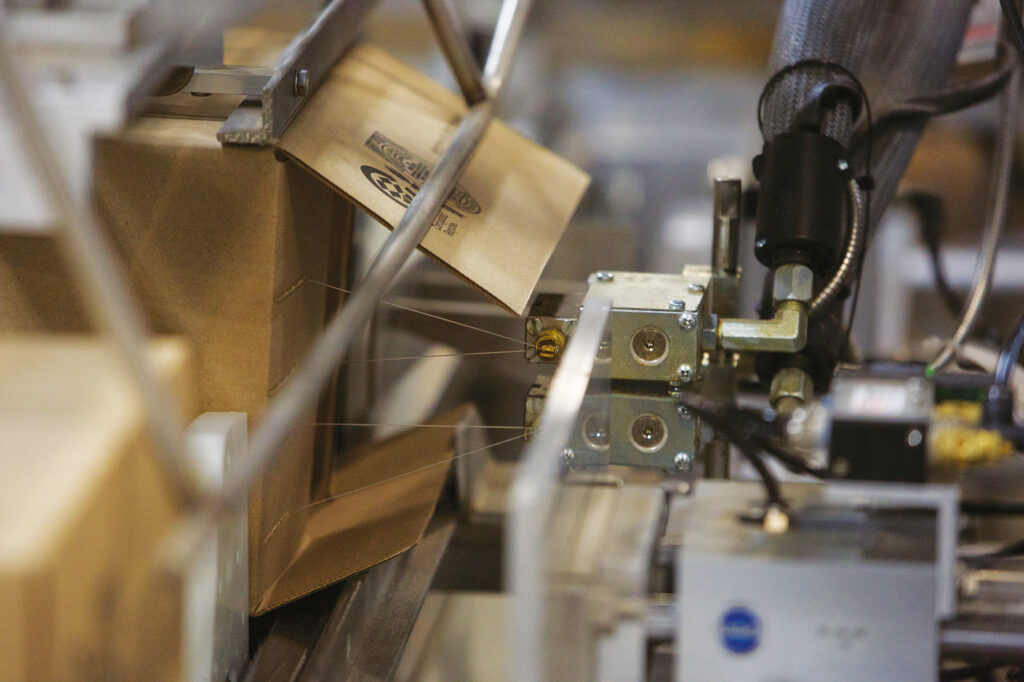

You’re in the middle of a critical production run when everything comes to a halt. The culprit? Stringing, also known as “angel hair.” This common issue with industrial adhesives is anything but angelic. It can create a tangled mess, decrease output, and increase costs. Let’s examine the causes and how you can avoid it.

4 Surprising Factors Contributing to Stringing of Industrial Adhesives

This phenomenon occurs when adhesives form thin threads during application, typically leading to inefficiencies and product defects. Here are some factors that contribute to this problem:

Airflow

A common issue with air flow is improper air pressure being supplied to the applicator, which is critical for ensuring consistent and effective adhesive distribution. Proper air pressure helps control the flow rate and pattern of the adhesive, directly impacting the quality of the bond.

Temperature

The temperature of the adhesive is crucial. Adhesives are sensitive to both low and high temperatures. If it’s too low, the adhesive becomes too viscous and strings as it exits the nozzle. Conversely, if it’s too hot, it can also string, a process similar to cheese stretching when a hot pizza is sliced.

Contamination

A partially clogged nozzle can cause ‘angel hair’ by reducing the orifice size, which increases the velocity of the adhesive as it exits, causing it to land erratically.

Timing and Bead Placement

Improper timing and bead placement can also lead to issues. If the adhesive bead fires too early, it can wrap around the substrate, dragging the adhesive and creating strings.

The Best Ways to Avoid Industrial Adhesive Stringing

To prevent stringing, it’s essential to use the right adhesive, maintain proper equipment settings, and perform regular preventative maintenance. Here are some actionable steps if you encounter stringing:

Control Airflow

In many cases, ensuring your adhesive equipment is set to the proper pressure will eliminate this problem and will help you avoid issues such as over-application, under-application, or uneven spread, all of which can compromise the adhesive’s performance. By maintaining the correct air pressure, you achieve a precise and reliable application, resulting in strong and durable bonds.

Optimize Temperature

Monitor and adjust the adhesive temperature to maintain the optimal viscosity. Typically, you’ll want to increase the temperature if the adhesive is too thick and decrease it if it’s too thin, ensuring you stay within the adhesive’s recommended temperature range.

Clean and Maintain Equipment

Regularly inspect and clean nozzles to prevent partial clogs. Replace worn or damaged components on your machines to ensure a consistent adhesive flow.

Adjust Timing and Placement

Fine-tune the timing and placement of adhesive beads. Ensure that the adhesive is applied at the right moment to avoid contact with substrates that could drag and create strings. Also, the closer to the nozzle tip to the substrate the better. Our technicians recommend 1/4″ to 1/2″ between the tip and the substrate.

How to Stop Stringing and Maximize Production

At APPLIED Adhesives, we understand the challenges that stringing can pose to your production line. Our extensive range of industrial adhesives, advanced equipment solutions, and expert maintenance services can help you tackle this issue effectively. We offer tailored industry solutions, including:

Lab Services

Our lab testing ensures you have the right adhesive before it ever hits your production lines. Whether you’re looking for hot-melt adhesives, sealants, or fast-curing glues, our industrial adhesives are designed to perform optimally under specific conditions, reducing the likelihood of stringing.

Advanced Industrial Adhesive Equipment

We are the distributors of top adhesive application equipment that ensures precision and reliability. These machines are designed to maintain the correct adhesive temperature and application distance, which are crucial factors in preventing stringing. By utilizing our advanced machinery, you can achieve consistent adhesive application, reducing waste and improving overall efficiency.

Preventative Maintenance and Training

Our preventative maintenance services help keep your adhesive equipment in top condition, minimizing downtime and production disruptions. Regular maintenance ensures that your adhesive application systems are operating at peak performance, which helps prevent common issues like nozzle clogging and uneven adhesive flow that can lead to stringing.

Our maintenance plans are tailored to your specific equipment and usage patterns, providing peace of mind and prolonging the lifespan of your machinery. We can also perform emergency maintenance and provide training for your employees.

Expert Adhesives Support and Troubleshooting

Don’t let stringing slow you down. Our experienced technicians can help diagnose and resolve issues quickly, ensuring that your production line runs smoothly. Whether it’s adjusting equipment settings, recommending the right adhesive for your application, or providing on-site training, the APPLIED Adhesives team has you covered.

Contact APPLIED Adhesives today to learn more about how we can help you achieve the best results with your adhesive applications.